3D Printing

Introduction

The Slicing software we will be using for this topic is called Cura

After creating 3D models in Fusion 360, the models can be imported as a STL file into Cura, which can then bring the models to life.

However, even 3D printers have their limits and these limitations can be grouped into 4 categories.

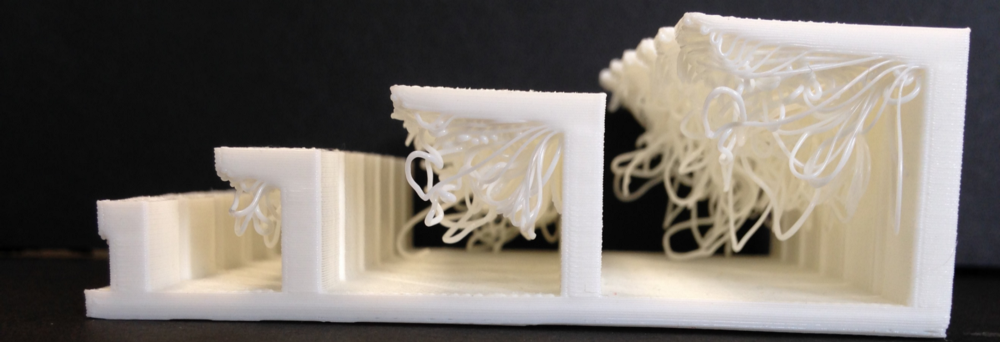

OverHangs

Any part of a print that extends outwards without any support structures is known as a overhang.

Without anything to support the print, the part that is overhang will result in the material dripping downwards.

Solution

Simply adding a support structure that can be ripped out of the model afterwards will fix this problem.

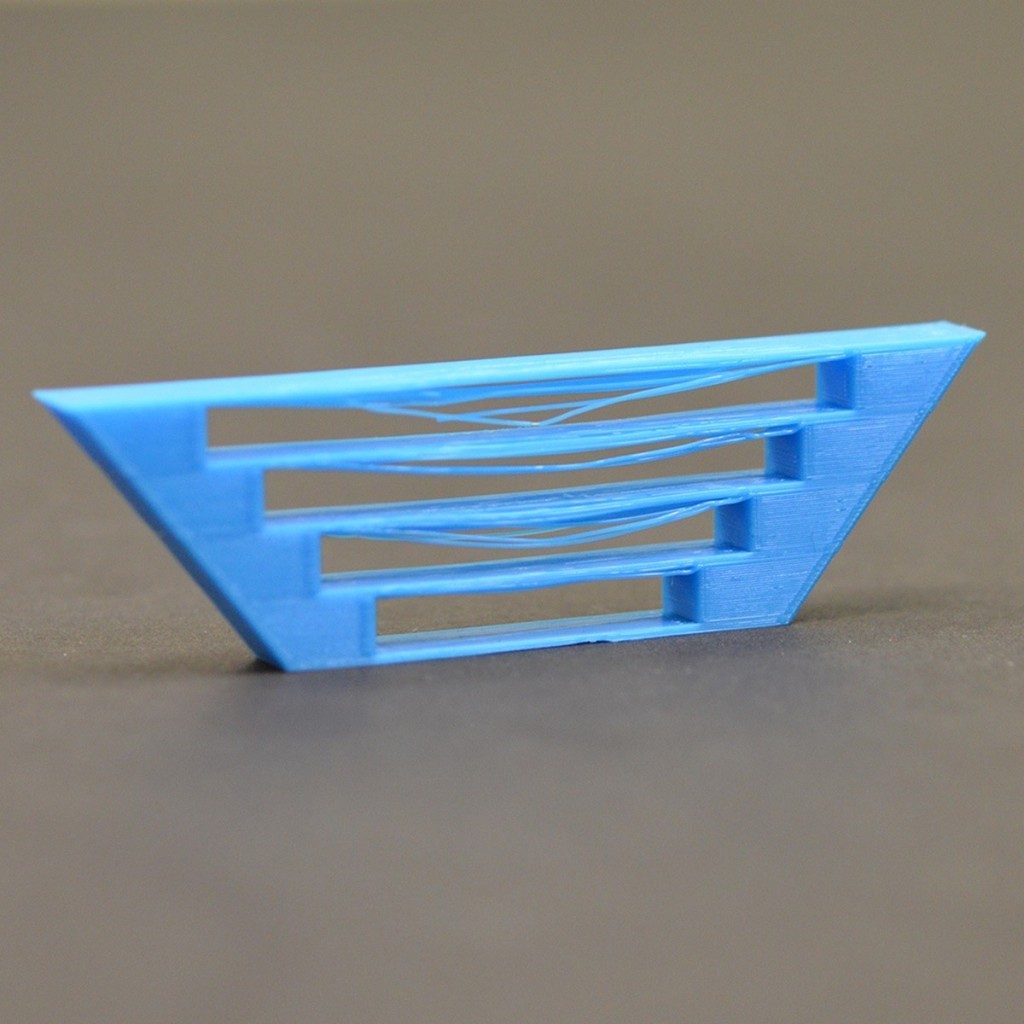

Bridging

Bridging is very similar to an overhang.The only difference is that bridging involves linking two raised points horizontally

Solution

Same as overhang

Raft , Brim and Skirts

Raft ,Brim and Skirts are something like base supports that ensure that printing goes smoothly so that the print material will not go to waste.

Raft

Raft is used to support 3D prints ,with small bases, by creating a strong foundation. Raft also improves bed adhesion and prevent warping.However a raft uses a lot of material.

Brim

Brim is very similar to Raft except that Brim isnt as strong of a support and is used to hold down the edges of a print.

Like Raft , it also improves bed adhesion and prevent warping.

Skirt

Skirt does not serve as a base support unlike Raft and Brim , instead it is used for priming the extruder and early detection of any printing errors.

Infills

Infills are what make up the inner structure of a print.

Infill density

A high infill density makes the print heavier and stronger.However it takes a lot longer , the denser the infill is. A low infill denisty makes the print more fragile and light but it uses way lesser materials and saves time.In Fablab, it is recommended that

- 10%-15% infill for prototyping

- 20%-25% for finalising prototypes

- 30%-35% for large objects and should be avoided if possible

- 50%-100% should never be used because it is really slow and wastes material

Bridge Testing

Group asignment

Here is a very simple model I created to test bridging, this model I made have a test range of 10mm to 50mm